Raise the level of your turnkey solutions.

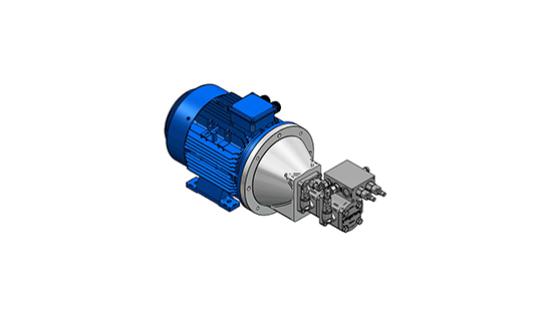

A machine tool is required to operate in infinite cycles, without missing a beat. It is required to maintain the tireless pace of production consistently, even under extreme conditions. And a Hydroven oleodynamic power unit is the component that makes all the difference in a machine tool.

We have been selected for our endurance, reliability and design capability by those who manufacture machinery and lines for processing stone, metal, wood, plastics and paper.

High Performance

Metal processing

These facilities are engineered to provide precise control over oil pressure and flow, enabling metal processing operations that are both high in performance and reliability.

Leveraging advanced technology and integrated safety features, Hydroven facilities guarantee efficient functioning and optimal protection for machinery and operators.

The capability to monitor and adjust operational parameters in real-time enhances the performance and productivity of the metal processing workflow.

Opting for a Hydroven hydraulic system means choosing quality, precision, and reliability to achieve outstanding results in metal processing.

Stone processing

Cutting, sanding, polishing, bush-hammering and many other processes are vital for the construction and cladding industries, especially when it comes to valuable materials such as marble or granite. The installation may vary depending on the type of stone and its intended use. This priority is in any case shared, with the activity having to take place correctly and safely in order to preserve the integrity of the material.

Hydroven’s oleodynamic power units provide reliable solutions for driving, lifting and controlling the operation of machinery, guaranteeing precision in every operation and certainty in the repeatability of the result.

Woodworking equipment

Processing wood has critical points and crucial steps that determine the quality of the final product. The utmost precision and attention to the material are required at every stage of the process.

Hydroven’s oleodynamic power units make it possible to precisely and safely control the movements of machines parts in motion, such as for saws, lathes, milling machines, lifting and handling systems, planing machines and presses.

Plastic processing

Plastic is one of the most versatile materials from which large-scale production of objects originates. Machines and plants used in this field are subjected to extreme production rhythms.

Blow moulding or injection moulding machines, for example, process plastic granulate through melting and shaping. Depending on the cadence and continuity of the process, the operating temperature is of paramount importance. Indeed, the temperature must allow the material to flow quickly into the injection mould without exceeding the limit, to avoid damage to the material itself.

The machine’s sub-systems, such as Hydroven’s hydraulic power units for example, ensure safe operation.

Paper production

Paper production mills are complex facilities due to facilitating the transformation of material from wet to dry. These plants carry out drying, finishing and winding phases in a continuous cycle, at a rapid pace. The finished product must then offer quality and thickness without any defects.

Hydroven’s oleodynamic power units ensure the necessary precision without stopping, guaranteeing constant control of the position and balance of the components, for a highly reliable result.

The use of high-quality components, combined with meticulous research and design, makes these hydraulic power units the best choice on the market for the paper industry.

Delivered

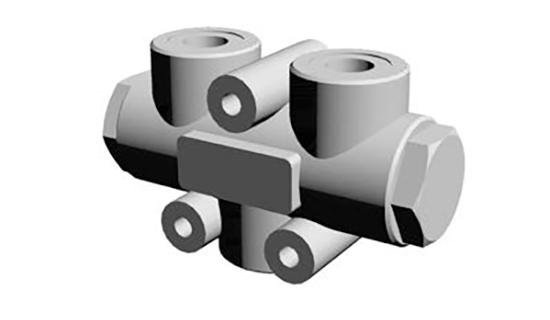

Components designed to last

We are convinced that only by choosing quality is it possible to guarantee oleodynamic components that last throughout the entire life cycle of the machine tool.

Hydroven and the Interpump Group

We are part of Interpump Hydraulics, which is in turn part of the Interpump Group. Our role as a system integrator triggers synergies that combine resources and expertise amongst over 130 different top players in the oleohydraulics and water jetting sectors.

Production capacity and stock

We satisfy major Original Equipment Manufacturers (OEMs) through the high availability of components in stock managed with planned procurement logic.

We have earned our position as a global player by providing timely answers and concrete solutions for thousands of industrial applications and vehicles.

Long-term partnerships

More research equals better outcomes. We invest in people and resources to achieve efficient products in mechanical performance, hydraulics and electronic integration, positioning ourselves as a bearer of innovation for the market. This aptitude is in our DNA and is the source of every long-lasting commercial and industrial relationship.

Other Hydroven solutions